In the world of logistics and supply chain management, effective handling and management of goods are paramount to ensuring smooth operations and customer satisfaction. Two terms that are often used interchangeably but have distinct meanings and applications are “stowage” and “storage.” Let’s delve into the differences between these two concepts to gain a clearer understanding of their roles in the logistics landscape.

- What is Stowage?

- What is Storage?

- Distinguishing Between Stowage vs Storage

- Boost Your Supply Chain with TFI

What is Stowage?

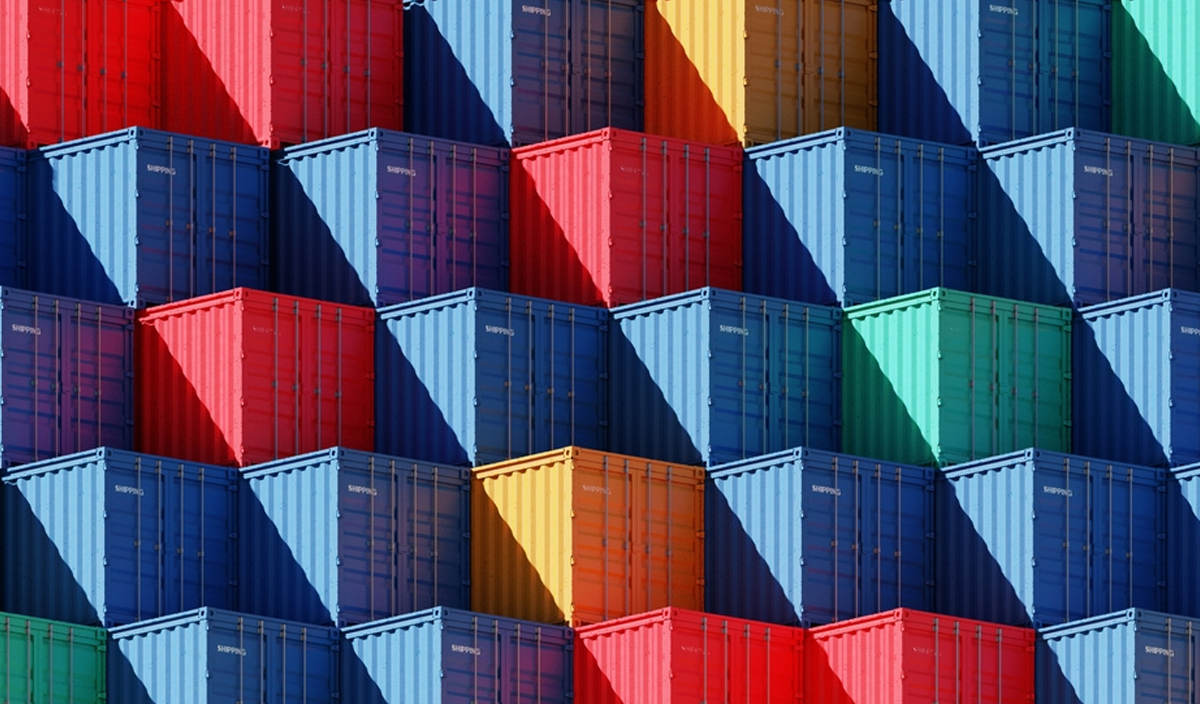

This activity refers to the strategic arrangement and placement of goods within a vehicle or container to optimize space, ensure stability during transit, and facilitate efficient loading and unloading processes. It’s primarily concerned with how items are positioned and secured for safe transportation, particularly on vessels, aircraft, or trucks.

Key aspects of stowage include:

- Space Optimization – Efficiently utilizing available cargo space to maximize capacity and minimize wasted space.

- Load Stability – Arranging goods to maintain balance and prevent shifting or movement during transit, reducing the risk of damage.

- Accessibility – Ensuring that cargo is positioned for easy access during loading and unloading operations, enhancing efficiency.

Stowage is critical for ensuring the safety and integrity of goods during transportation, where factors such as weight distribution, load-bearing capacity, and mode of transport play crucial roles in determining the stowage strategy.

What is Storage?

Storage involves the systematic and organized keeping of goods in a designated facility or area for a specific duration. Unlike stowage, which focuses on temporary arrangements for transit, storage is about maintaining inventory in a controlled environment to preserve quality, facilitate inventory management, and ensure goods’ security.

Key aspects of storage include:

- Inventory Management – Organizing goods within a warehouse or storage facility based on categories, usage frequency, or other criteria to optimize space and streamline retrieval.

- Security and Protection – Implementing measures such as surveillance, access controls, and climate control to protect goods from theft, damage, or environmental factors.

- Preservation – Creating suitable conditions (e.g., temperature-controlled environments, humidity regulation) to extend the shelf life and quality of stored items.

Storage is a fundamental component of supply chain management, enabling businesses to maintain adequate inventory levels, respond to customer demands promptly, and optimize resource utilization.

Distinguishing Between Stowage vs Storage

The primary difference between stowage vs storage lies in their focus and application within the logistics process. Stowage pertains to the arrangement and handling of goods during transit to ensure safe transportation, while storage involves the long-term safekeeping and management of inventory within a designated facility.

Both stowage and storage are essential aspects of logistics management, each serving unique purposes in optimizing the movement and storage of goods throughout the supply chain. By understanding these differences, businesses can implement effective strategies to enhance operational efficiency, minimize risks, and meet customer expectations effectively.

Boost Your Supply Chain with TFI

At TFI, our goal is to ensure your business’ success by offering a range of supply chain management solutions. We make this possible by combining our 30+ years’ expertise, global agent network, ISO-certified processes, and customs-bonded warehouse in Dubai South. The in-house experts in our UAE warehouse also collaborate with stakeholders to seamlessly integrate industry-leading practices and provide bespoke solutions suitable to your business’ needs.